Tubes

Most overhead cam engines manufactured since the late 1980’s have recessed spark plugs which are connected to the ignition system by high tension cables and a long rigid tube arrangement. The rigid tubes allow the lead to positively connect onto the spark plug terminal and ceramic, while at the same time sealing the top of the chamber against the ingress of moisture and other contaminants.

Occasionally these rigid tubes melt while in service. This should not and will not happen when the vehicle is used under normal operating conditions.

The rigid tube material is made from Poly Butylene Terephthalate or PBT for short. PBT is an excellent material for these applications.

It has the following characteristics:

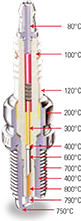

• PBT has a normal operating temperature range up to 210°C.

• PBT will not melt until it reaches 240°C.

• The hottest operating temperature of a spark plug ceramic is around 120°C, under normal conditions.

Why do tubes sometimes melt?

Under normal operating temperatures the PBT tube will function correctly for many years without incident. However, under severe engine overheating conditions the PBT tube will melt. This may come about from a cooling system failure, an overloaded engine, running the engine low on lubricating oil or in a limited number of situations from incorrect timing.

If the PBT tubes on an engine melt, we recommend that the cooling system be carefully checked. If the PBT tubes melt it is a consequence of engine and cooling system malfunction, lead failure is not the cause. Melted tubes will normally stop the engine from operating. This will limit the amount of consequential damage done to other engine parts. Most overhead cam engines are particularly sensitive to overheating, which can result in head gasket failure, camshaft damage and piston seizing.

Voltage puncture

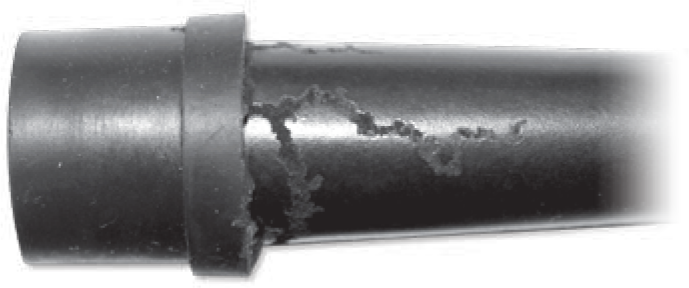

If an intermittent miss occurs, especially when the engine is under load, this could be caused by the PBT tube breaking down resulting in voltage arc, see photo.